Cold Room PVC STRIP CURTAIN

What Are Cold Room PVC Strip Curtains?

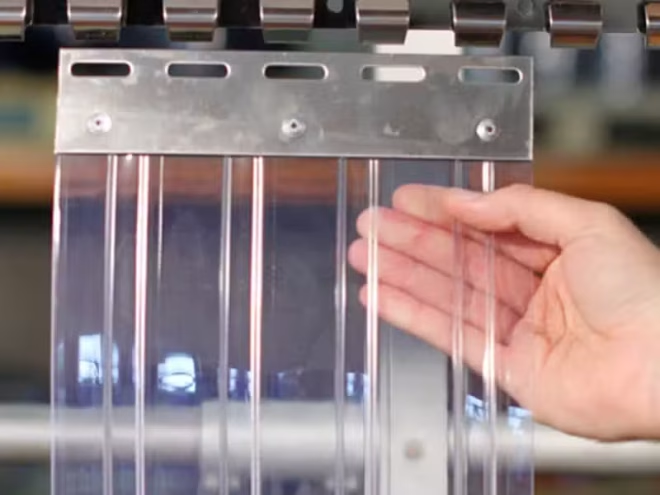

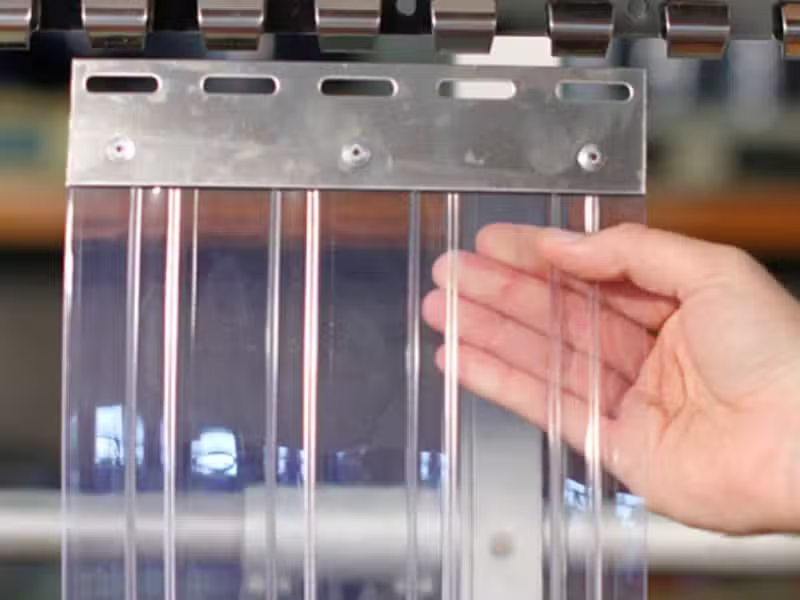

Cold room PVC curtains are specialized air curtains composed of flexible PVC strips that hang vertically from a top-mounted track. These curtains act as a dynamic barrier, allowing free movement of personnel and goods while preventing the exchange of hot and cold air between different areas. This innovative design not only maintains consistent temperature levels within cold rooms and storage areas but also enhances overall energy efficiency and hygiene standards.

In the highly competitive landscape of temperature-controlled environments, maintaining optimal conditions is crucial for ensuring product quality, operational efficiency, and energy conservation. Cold room PVC curtains by Tunel Group offer a sophisticated solution designed to meet these demands. These advanced curtains leverage cutting-edge PVC strip technology to create effective barriers against temperature fluctuations, frost formation, and energy loss, making them indispensable for industries such as food processing, pharmaceuticals, healthcare, and logistics.

Importance of Cold Room PVC Curtains

In environments where precise temperature control is essential, cold room PVC curtains play a pivotal role in:

- Energy Efficiency: Reducing the loss of conditioned air, thereby lowering energy consumption and operational costs.

- Temperature Control: Maintaining stable temperature levels by preventing unwanted air exchange, which is crucial for preserving sensitive products.

- Hygiene and Cleanliness: Minimizing the introduction of contaminants and moisture, thereby enhancing the cleanliness of storage and processing areas.

- Operational Flexibility: Allowing seamless movement of goods and personnel without compromising the integrity of the cold storage environment.

Features of Tunel Group’s Cold Room PVC Strip Curtains

- Smooth, Non-Porous Surfaces: Prevents microbial growth and ensures easy cleaning, maintaining a sterile environment.

- Advanced Insulation: High-performance panels minimize energy loss while maintaining consistent temperatures.

- Air Filtration Systems: HEPA filters eliminate airborne contaminants, enhancing hygiene and safety.

- Antimicrobial Coatings: Surfaces treated to inhibit bacterial and fungal growth, ensuring long-term cleanliness.

- Compliance with Standards: Fully compliant with HACCP, TSE, and EN standards, ensuring adherence to international hygiene and safety regulations.

- Environmentally Friendly Design: Energy-efficient systems using eco-friendly refrigerants promote sustainable operations.